ASTM A335 Grade P5 Seamless Pipe

GR.P5 A335 Ferritic Alloy Steel Seamless Pipes

ASTM A335 Gr P5 Seamless Pipe Manufacturers, ASME SA335 Grade P5 Alloy Steel Pipes Suppliers in Mumbai, India.

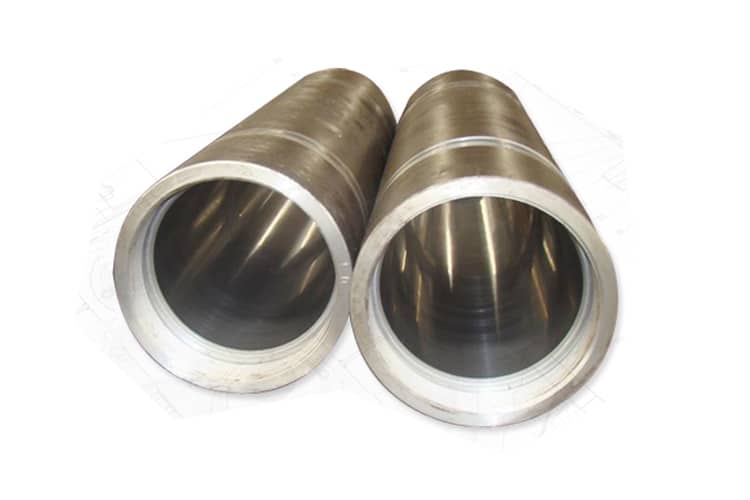

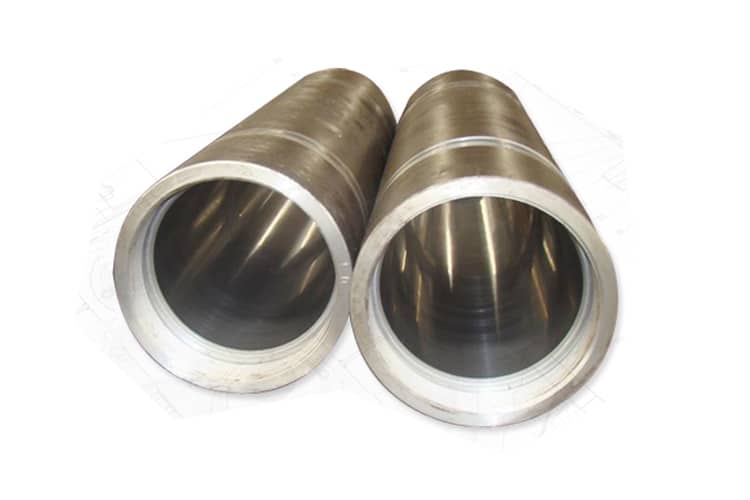

Kencotube is reputed manufacturer & stockiest of ASTM A335 Gr P5 Alloy Steel Seamless Pipes, which has subsequent addition of chromium, molybdenum and sometimes vanadium are known as chrome moly Pipes. ASTM A335 Gr P5 Alloy Steel Pipes are used for high temperature service applications, which are reheated and furnished in full annealed, isothermal annealed or normalised quenched and tempered condition. ASME SA335 Gr P5 Alloy Steel Seamless Pipes have a typical chemistry with additions of Molybdenum, covering nominal wall and minimum wall seamless ferritic alloy-steel pipe intended for high-temperature service. ASME SA335 Gr P5 Alloy Steel Pipes shall be suitable for bending, flanging, and similar forming operations, and for fusion welding, where selection of the same will depend upon design, service conditions, mechanical properties, and high-temperature characteristics.

A335 P5 High Temperature Seamless Pipe, ASTM A335 P5 Alloy Steel Seamless Boiler Pipes, ASME SA335 Seamless Pipes, Alloy Steel Pipe, Alloy Steel Seamless Pipe, ASTM A335 Grade P5 Alloy Steel Seamless Pipes Suppliers, A335 gr P5 Seamless Pipes Exporters, ASTM A335 Gr P5 Seamless Pressure Pipe, Alloy Steel P5 Seamless Pipe, Alloy Steel UNS K51545 Seamless Pipes, ASTM A335 Gr P5 Ferritic Alloy Steel Seamless Pipes, Alloy Steel Thick Wall Large Diameter Pipes Manufacturers and Stockists.

ASTM A335 Alloy Steel Grade P5 Seamless Pipes may be either hot finished or cold drawn with the finishing treatment, which can be further provided in quenched and tempered conditions. ASTM A335 Alloy Steel Grade P5 Pipes are used in construction, electrical and engineering industries, which are in addition accredited among our clients due to their high tensile strength, fine finish and durability. ASME SA335 Alloy Steel Grade P5 Seamless Pipes has characteristics like deep drawing quality, excellent toughness, low temperature properties responding well to hardening by cold working & forming & welding properties. We also offer the same at reasonable cost in different sizes and shapes to our clients.

ASTM A335 P5 Chrome Moly Alloy Steel Pipe, ASTM A335 Grade P5 Seamless Square Pipes Distributors, P5 Alloy Steel Seamless Round Pipe, SA 335 Gr P5 Seamless Rectangular Pipes, P5 Alloy Steel Cold Rolled Seamless Pipes, A335 Grade P5 Hot Rolled Alloy Steel Seamless Pipes Stockholders.

| Specifications | ASTM A 335 / ASME SA 335 |

| Size | 1/8"NB TO 30"NB IN |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS, UPTO 4″ WALL THICK |

| Length | Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths |

| Form | Round, Square, Rectangular, Hydraulic Etc. |

| Type | Seamless |

P5 Material Chemical Composition

| Grade | C % | Mn % | P % | S % | Si % | Cr % | Mo % |

|---|---|---|---|---|---|---|---|

| P5 | 0.05-0.15 | 0.30-0.60 | 0.025 max | 0.025 max | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

P5 Mechanical Properties

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P5 | 415 min | 205 min | 30 min |

Our City-wise Supply :

Howrah, Jeddah, Riyadh, Bogota, Petaling Jaya, Dallas, Lagos, Nagpur, Houston, Brisbane, Busan, Karachi, Coimbatore, Seoul, Caracas, Atyrau, Perth, Haryana, Bengaluru, Jaipur, Al Jubail, Kuwait City, Al Khobar, Sydney, Ranchi, Chiyoda, Noida, Chandigarh, Secunderabad, Ahvaz, Port-of-Spain, Singapore, Gurgaon, Rajkot, Rio de Janeiro, Abu Dhabi, Hong Kong, Surat, Sharjah, Hanoi, London, Muscat, Jakarta, Navi Mumbai, Istanbul, Kolkata, Cairo, Mumbai, Santiago, Montreal, Faridabad, Vung Tau, Bangkok, Ankara, Ahmedabad, Granada, Melbourne, Tehran, Visakhapatnam, New Delhi, Los Angeles, Ho Chi Minh City, Edmonton, La Victoria, Baroda, Thane, Nashik, Kuala Lumpur, Moscow, Ernakulam, Courbevoie, Calgary, Geoje-si, Indore, New York, Mexico City, Gimhae-si, Ludhiana, Kanpur, Ulsan, Thiruvananthapuram, Manama, Doha, Chennai, Madrid, Jamshedpur, Algiers, Dammam, Bhopal, Lahore, Milan, Hyderabad, Pune, Vadodara.

Our International Supply chain :

Chile, Brazil, Nigeria, Belgium, Australia, Ecuador, Trinidad & Tobago,Tunisia, Chile, Nigeria, Philippines, Taiwan, Pakistan, Egypt, Tibet, Italy, Estonia, Saudi Arabia, Venezuela, New Zealand, Nepal, Poland, Ukraine, Czech Republic, Bulgaria, Poland, Belarus, Finland, Denmark, South Korea, Colombia, Argentina, Norway, Vietnam, Bangladesh, Yemen, Turkey, China, Namibia, Bolivia, Portugal, Macau, Switzerland, Mexico, India, Indonesia, Libya, Kuwait, Thailand, Japan, Spain, Iran, Azerbaijan, Greece, Sri Lanka, Slovakia, Singapore, Gambia, Austria, Mexico, Costa Rica, Oman, Mongolia, Russia, Croatia, United Arab Emirates, Germany, Sweden, Algeria, Zimbabwe, Ghana, Lithuania, Bhutan, Iran, Qatar, Gabon, South Africa, Hungary, United Kingdom, Puerto Rico, Morocco, Canada, Ireland, Lebanon, Kenya, Netherlands, Kazakhstan, Peru, Jordan, Iraq, Israel, Bahrain, Afghanistan, Romania, Malaysia, France, Angola, United States, Serbia, Hong Kong.

Alloy Steel Pipe