ASTM A335 Grade P22 Seamless Pipe

GR.P22 A335 Ferritic Alloy Steel Seamless Pipes

ASTM A335 Gr P22 Seamless Pipe Manufacturers, ASME SA335 Grade P22 Alloy Steel Pipes Suppliers in Mumbai, India.

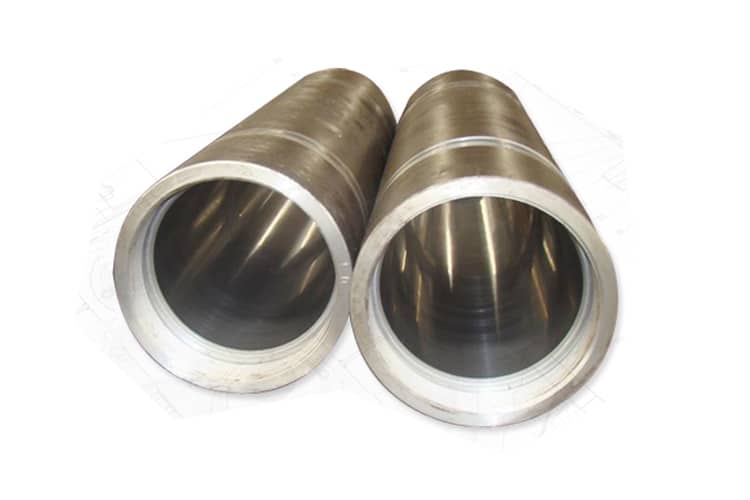

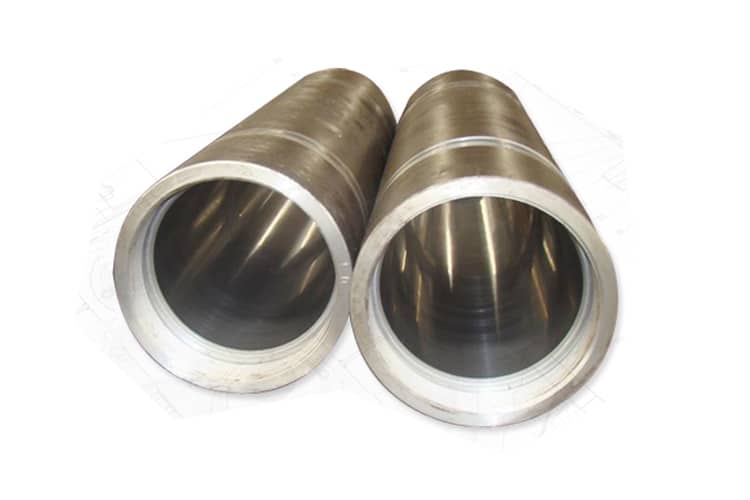

Kencotube is manufacturer & supplier of ASTM A335 Gr P22 Alloy Steel Seamless Pipes, who have developed this specification to decide the manufacturing process and testing standards of this alloy steel pipe. ASTM A335 Gr P22 Alloy Steel Pipes shall be suitable for bending, flanging, and similar forming operations, and for fusion welding. The range of ASME SA335 Gr P22 Alloy Steel Seamless Pipes that may be examined by each method shall be subjected to the limitations in the scope of the respective practice.The different mechanical test requirements for ASME SA335 Gr P22 Alloy Steel Pipes, namely, transverse or longitudinal tension test, flattening test, and hardness or bend test are presented. Both ends of ASTM A335 Alloy Steel Grade P22 Seamless Pipes will indicate the order no., heat no., dimensions, weight and bundles or as requested.

Alloy Steel Pipe, Alloy Steel Seamless Pipe, ASTM A335 Grade P22 Alloy Steel Seamless Pipes Suppliers, A335 gr P22 Seamless Pipes Exporters, ASTM A335 Gr P22 Seamless Pressure Pipe, Alloy Steel P22 Seamless Pipe, Alloy Steel UNS K21590 Seamless Pipes, ASTM A335 Gr P22 Ferritic Alloy Steel Seamless Pipes, Alloy Steel Thick Wall Large Diameter Pipes, A335 P22 High Temperature Seamless Pipe, ASTM A335 P22 Alloy Steel Seamless Boiler Pipes, ASME SA335 Seamless Pipes Manufacturers and Stockists.

ASTM A335 Alloy Steel Grade P22 Pipes is virtually irreplaceable in resisting oxidation at elevated temperatures, where it raises the tensile, yield, and hardness at room temperatures. ASME SA335 Alloy Steel Grade P22 Pipes is an austenitic chromium nickel stainless steels which is used for higher temperature applications. ASME SA335 Alloy Steel Grade P22 Seamless Pipes makes it ideal for use in power plants, refineries, petro chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures. Kencotube also offer these pipes in cost-effective rates along with in customized sizes and shapes to esteemed clients.

ASTM A335 Grade P22 Seamless Square Pipe Distributors, P22 Alloy Steel Seamless Round Pipe, SA 335 Gr P22 Seamless Rectangular Pipes, ASTM A335 P22 Chrome Moly Alloy Steel Pipe, P22 Alloy Steel Cold Rolled Seamless Pipes, A335 Grade P22 Hot Rolled Alloy Steel Seamless Pipes Stockholders.

| Specifications | ASTM A 335 / ASME SA 335 |

| Size | 1/8"NB TO 30"NB IN |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS, UPTO 4″ WALL THICK |

| Length | Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths |

| Form | Round, Square, Rectangular, Hydraulic Etc. |

| Type | Seamless |

P22 Chemical Composition

| Grade | C % | Mn % | P % | S % | Si % | Cr % | Mo % |

|---|---|---|---|---|---|---|---|

| P22 | 0.05 - 0.15 | 0.30 - 0.60 | 0.025 max | 0.025 max | 0.50 max | 1.90 - 2.60 | 0.87 - 1.13 |

P22 Mechanical Properties

| Grade | Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

|---|---|---|---|

| P22 | 415 min | 205 min | 30 min |

Our City-wise Supply :

Thiruvananthapuram, Noida, Gurgaon, Ernakulam, Gimhae-si, Melbourne, Ludhiana, New Delhi, Kolkata, Doha, Rio de Janeiro, Busan, Chiyoda, Coimbatore, Riyadh, Mumbai, New York, Jeddah, Moscow, Rajkot, Faridabad, Hyderabad, Abu Dhabi, Bhopal, Edmonton, Pimpri-Chinchwad, Thane, Nashik, Karachi, Courbevoie, Vung Tau, Mexico City, Kanpur, Hanoi, Muscat, Pune, Ahmedabad, Ho Chi Minh City, Colombo, Dammam, Kuala Lumpur, London, Petaling Jaya, Sharjah, Haryana, Secunderabad, Toronto, Atyrau, Madrid, Baroda, Visakhapatnam, Seoul, Geoje-si, Ulsan, Indore, Calgary, Chandigarh, Bengaluru, Bangkok, Bogota, Howrah, Jaipur, Algiers, Brisbane, Jakarta, Dubai, Ranchi, Port-of-Spain, Aberdeen, Kuwait City, Los Angeles, Surat, Al Khobar, Manama, Hong Kong, Vadodara, Singapore, La Victoria, Milan, Lagos, Montreal, Perth, Dallas, Ahvaz, Sydney, Tehran, Houston, Lahore, Jamshedpur, Caracas, Chennai, Navi Mumbai, Nagpur.

Our International Supply chain :

Denmark, Peru, Vietnam, Canada, Ukraine, Mexico, Israel, Gabon, Bulgaria, Sri Lanka, Poland, Croatia, Nepal, Nigeria, Jordan, Nigeria, Trinidad & Tobago,Tunisia, Netherlands, Taiwan, Libya, Belgium, Algeria, Costa Rica, Morocco, Brazil, Hong Kong, Mongolia, Philippines, Namibia, New Zealand, Zimbabwe, South Africa, Ireland, United Arab Emirates, Ecuador, United States, Sweden, Turkey, Mexico, Venezuela, Austria, Czech Republic, Serbia, Angola, Bangladesh, Estonia, Singapore, Pakistan, Yemen, Japan, Italy, Saudi Arabia, India, Norway, Spain, Tibet, Hungary, Colombia, Argentina, Greece, Bhutan, Lithuania, United Kingdom, Iraq, Puerto Rico, Switzerland, Lebanon, Iran, Gambia, France, Thailand, Ghana, Oman, Portugal, Egypt, Kazakhstan, Kenya, Bahrain, Indonesia, Kuwait, South Korea, Afghanistan, Macau, Chile, Qatar, China, Belarus, Chile, Germany, Romania, Azerbaijan, Russia, Iran, Finland, Malaysia, Bolivia, Slovakia, Poland, Australia.

Alloy Steel Pipe