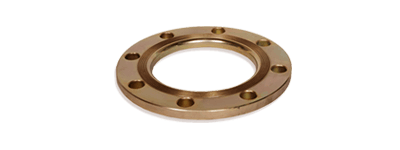

Copper Nickel Flange

Copper Nickel Industrial Flanges

ASME SB151, SB152 Copper Nickel Flanges Manufacturers, ANSI B16.5, ANSI B16.47, ANSI B16.36 Cupro Nickel Flanges, ASTM B61, B62 UNS C70600 / C71500 Flanges Suppliers in Mumbai, India.

A Copper Nickel Flange is exceptionally durable and corrosion-resistant. In piping systems with corrosive fluids, it is widely utilized. Due to the nickel component, this alloy can endure high temperatures and brine solutions. These flanges are well suited for use in the electric power, offshore, and natural gas pipeline industries. Copper Nickel Flanges have been proven to have many good attributes since the early days. Copper Nickel Pipe Flanges have very high corrosion resistance, but there was concern about their low corrosion-fatigue strength. Copper Nickel Alloy Flanges show corrosion resistance parallel to copper, greater general power, and enhanced fatigue strength. Copper Nickel Alloy Pipe Flanges provide superior reliability and assure both manufacturers and vehicle owners of improved durability. The rudimentary procedure of alloying utilizing other materials and metals in Cu-Ni Flanges has made substantial assistances to our contemporary society and assurances to ensure supplying materials for a more challenging future. These Cupronickel Flanges are highly alloyed with aluminium, chromium, or tin that is used where more excellent resistances to seawater flow, sand abrasion, wear, and galling, as well as higher mechanical properties, are required.

Copper Nickel Alloy Flanges, Copper Flange, Cu-Ni 90/10 (C70600) Flange, Cu-Ni 70/30 (C71500) Flanges Exporters, Cupro Nickel Flange, ASME B61 Copper Nickel Slip-On Flanges Manufacturers, Copper Nickel Blind Flanges, Copper Nickel Socket Weld Flanges, ASTM B151 Copper Nickel Alloy Threaded Flanges Suppliers.

In marine and seawater projects, copper-nickel flanges are frequently utilized. Copper Nickel can tolerate the enormous quantities of dissolved salt and chemicals in seawater despite its corrosive nature. The impacts of organic chemicals and brine water cannot harm copper-nickel. Moreover, Copper Nickel is resistant to marine organisms thanks to its antibacterial touch surface. Cu-Ni Alloy Flanges are also used for thermocouples as it develops a high and uniform EMF when coupled with other metals such as copper and iron. Good formability allows ease of flaring and bending. Although the metal cost is more excellent than steel alternatives, Cupronickel Alloy Flanges are attractive given their different life, trouble-free installation, and safety/reliability characteristics. Cu-Ni Alloy Pipe Flanges have offered consistent service for many years while providing operative solutions to present-day technological challenges. Cupronickel Alloy Pipe Flanges have unique quality finishing, high pressure, duress for long life, and zero defects.

ASTM B62 Copper Nickel Weld-Neck Flanges, Copper Nickel Alloy Spectacle Flanges, Copper Nickel Lap-joint Flanges Stockholders, ASME SB152 Copper Nickel Orifice Flanges, Copper Nickel Forged Flanges Dealers, Copper Nickel Alloy Plate Flanges, Copper Nickel Loose Flanges Manufacturers, Copper Nickel Groove Flanges Stockists.

Copper-Nickel flanges are made of Copper-Nickel alloy, a material that combines the properties of copper and nickel. These flanges connect sections of pipes or tubes, creating a tight and leak-proof seal.

Copper-Nickel flanges have excellent corrosion resistance, particularly in marine environments. They also have good strength & ductility, & are resistant to stress corrosion cracking. They have high thermal conductivity & are easy to machine.

Copper-Nickel flanges are commonly used in marine and offshore applications such as ships, desalination plants, oil & gas production platforms. They are also used in saltwater piping systems & in coastal power plants. They are also used in chemical processing, desalination, & other corrosive environments.

Copper-Nickel flanges typically conform to ASME B16.5 & ASTM B122 standards, & they also can be manufactured according to the customers' design requirements.

| Specifications | ASTM B61, B62, B151, B152 / ASME SB61, SB62, SB151, SB152 |

| Standards | ASTM, ASME Flanges, ANSI Flanges, DIN Flanges, EN Flanges, BS Flanges etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Size | 1/2" 36" |

| Pressure Ratings | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 |

| Grade | UNS NO. C92200 & UNS NO. C83600, UNS NO. C70600 ( CU -NI- 90/10), C71500 ( CU -NI- 70/30), ASTM / ASME SB 152 UNS NO C10100, C10200, C10300, C10800, C12000, C12200. |

| Flanges Types | Expander Flanges, Forged Flanges, Blind Flanges, Reducing Flanges, Orifice Flanges, Socket Weld Flanges, Slip On Flanges, Flat Flanges, Lapped Joint Flanges, High Hub Blinds Flanges, Nipo Flanges, Threaded Flanges, Square Flanges, Long Neck Weld Flanges, RTJ Flanges etc |

Copper Nickel Alloy Equivalent Grade

| STANDARD | WERKSTOFF NR. | UNS |

|---|---|---|

| Copper Nickel 90/10 | 2.0872 | C70600 |

| Copper Nickel 70/30 | 2.0882 | C71500 |

Copper Nickel Chemical Composition

| Grade | Cu | Pb | Mn | Fe | Zn | Ni |

|---|---|---|---|---|---|---|

| Cupro Nickel 90/10 | 88.6 min | .05 max | 1.0 max | 1.8 max | 1 max | 9-11 max |

| Cupro Nickel 70/30 | 65.0 min | .05 max | 1 max | 0.4-1.0 | 1 max | 29-33 |

Copper Nickel Mechanical Properties

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Cu-Ni 90/10 | 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

| Cu-Ni 70/30 | 0.323 lb/in3 at 68 F | 2260 F | 50000 psi | 20000 psi | 30 % |

Our City-wise Supply :

Navi Mumbai, Chandigarh, Al Khobar, Edmonton, Mumbai, Caracas, Doha, Hyderabad, Abu Dhabi, Singapore, Karachi, Vung Tau, Jeddah, Mexico City, Calgary, Surat, Bhopal, Courbevoie, Seoul, Gurgaon, Perth, Ahvaz, Brisbane, Hong Kong, Dammam, Lagos, Jaipur, Howrah, Houston, Milan, Ho Chi Minh City, Manama, Chiyoda, Ranchi, New York, Rajkot, Noida, Visakhapatnam, Los Angeles, Petaling Jaya, Atyrau, Bangkok, Sharjah, Chennai, Coimbatore, Ankara, New Delhi, Nashik, Indore, Madrid, Muscat, Toronto, Thane, Sydney, Gimhae-si, Jamshedpur, Port-of-Spain, Dallas, Busan, Melbourne, Kolkata, Kuwait City, Dubai, Haryana, Al Jubail, Ahmedabad, Baroda, Istanbul, Colombo, Lahore, Riyadh, Bengaluru, Faridabad, Hanoi, Secunderabad, Granada, Aberdeen, Ludhiana, Geoje-si, Pune, Moscow, Vadodara, Pimpri-Chinchwad, Ulsan, Kanpur, La Victoria, Bogota, Santiago, Montreal, Ernakulam, Tehran, Rio de Janeiro, Nagpur, Thiruvananthapuram.

Our International Supply chain :

Lithuania, Mexico, Romania, Bolivia, Germany, Denmark, Pakistan, Ecuador, Tibet, Hong Kong, France, Trinidad & Tobago,Tunisia, Austria, Iran, Czech Republic, Canada, Slovakia, Switzerland, Mexico, Israel, Costa Rica, Brazil, South Africa, Namibia, India, Serbia, Nigeria, Greece, Poland, Colombia, Sri Lanka, Yemen, Algeria, Bahrain, Taiwan, United Arab Emirates, China, Netherlands, Sweden, Iraq, Indonesia, United Kingdom, Angola, Chile, Thailand, Portugal, Singapore, Libya, Puerto Rico, Ghana, New Zealand, Belgium, Macau, Croatia, Norway, Bulgaria, Nepal, Belarus, South Korea, Iran, Saudi Arabia, Japan, Hungary, Philippines, Nigeria, Lebanon, Morocco, Russia, Kazakhstan, Spain, Bangladesh, Kuwait, Estonia, Jordan, Kenya, Poland, Mongolia, Zimbabwe, Afghanistan, Ukraine, Qatar, Ireland, United States, Gambia, Vietnam, Egypt, Bhutan, Finland, Azerbaijan, Turkey, Argentina, Chile, Australia, Venezuela, Italy, Malaysia, Peru, Oman, Gabon.

Flanges